Compounding System Solution

Ideal provides various dosage forms of material preparation system for pharmaceutical companies. For different product requirements of each client, we provide technical solutions from concept design, scheme design and detailed design, equipment manufacturing, installation and commissioning, training, operation and maintenance to validation.

For multi-tank preparation system, advanced adapter plate design process is adopted. Tank cleaning can be completely independent of pipe, so as to avoid leakage of materials, pollution and risk of false operation. In this way, less dead ends will present in pipe system and cleaning will be easier.

Piping and equipment meets requirements of GMP production, without blind pipe and dead ends. Installation of equipment and accessories facilitates disassembly, maintenance and repair.

Structure design of steel platform is reasonable, so it will be easy for operating and carrying out all kinds of cleaning work.

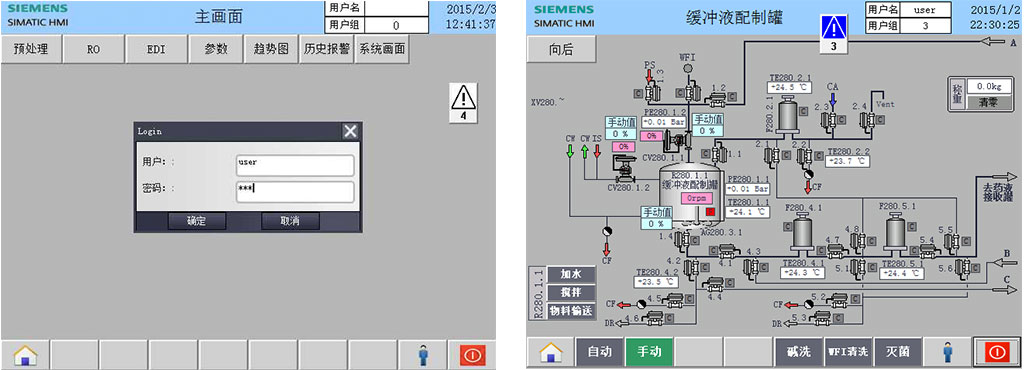

Control system meets operation requirements of production process, and automatic control of online cleaning, sterilization, material transfer, etc. can be realized. Relevant parameters of preparation system can be monitored and recorded in real time, to ensure quality tracking and tracing.

After detailed design and before construction, the whole system will be three-dimensional designed according to layout of field equipment.

Service Scope:

Oral liquid preparation system

Sterile preparation system

Extraction preparation system

Cream and eye ointment preparation system

CIP system

Bioengineering