R&D

Ideal sets up a practical, efficient and independent R&D team which committed to research and development of pharmaceutical equipment, in order to meet needs of pharmaceutical industry, improve efficiency, reduce costs and energy consumption, also provide better service in pharmaceutical process system.

Ideal has obtained various product patents

01. New pure steam samplerPure steam sampler is used for detection of pure steam quality, and inspection criterion is whether condensate water of pure steam conforms to standards of WFI. New pure steam sampler uses freon, lithium bromide, etc. as cooling medium, whose liquefaction and gasification temperature is close to normal temperature. Original spiral cooling condenser tube is changed to spray condenser tube, so that cooling medium is ejected from spray condenser tube in liquid state. When encountering hot pure steam in condenser tube, gasification will be done immediately at the moment liquid cooling medium absorbs heat. Such liquid and gas conversion makes heat exchange efficiency higher. At the same time, huge cooling water tank structure of traditional sampler can be saved, so volume of pure steam sampler is more compact and portable. It is also added a small compressor, so heat absorbed cooling medium will be squeezed into liquid, and releasing heat in the process. New sampler can be used for a long time, and do not need to worry about water in cooling tank is too hot to reduce cooling efficiency of hot pure steam. And new sampler has advantages of small volume and convenient movement, so it can meet the demands of clients better.

|

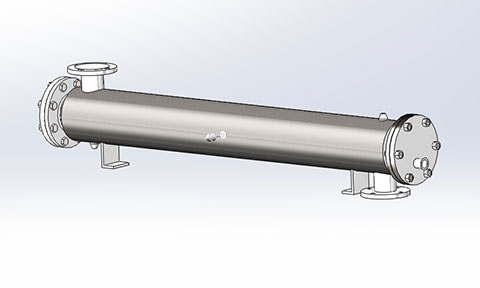

02. U type double-tube plate heat exchangerU type double-tube plate heat exchanger adopts sterile design and can completely avoid cross contamination. It is widely used in the field of bio pharmaceutical, such as occasions of material preparation, cooling and heating of WFI, and sterilization of pharmaceutical water. The U type double-tube plate heat exchanger is added shell turbulence device, which greatly improves efficiency, reduces area and shortens time of heat exchanger. The double-tube plate design completely separates shell and tube sides to ensure no pollution. Tubes in heat exchanger presents no dead ends, and during atmospheric emptying, sanitary side liquid can be completely discharged from heat exchanger; during running, gas will never exist in sanitary side or heat exchanger. The structure reasonably avoids internal stress caused by expansion and contraction of shell and tube sides.

|

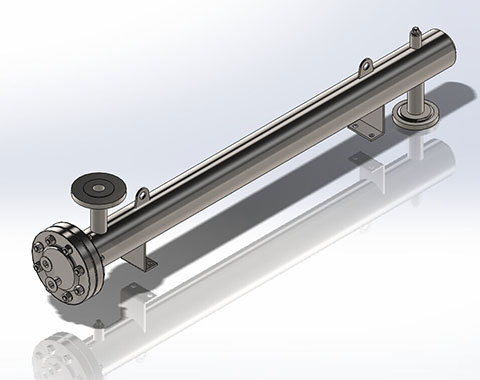

03. Three-layer casing condenserThree-layer casing condenser is applied to cooling process of steam condensate water and high temperature water. Three-layer casing condenser has small volume and simple structure. Three- layer casing structure makes cooling water enter inner and outer condensate water channel (i.e. middle casing). Spiral spoiler and disturbance spiral rib with different screw diameters are arranged between inner and two outer sleeves, to improve turbulence phenomenon and improve efficiency of heat exchanger. Both ends are respectively connected to input and output of inner sleeve, middle sleeve and outer sleeve with clamp joints, which solves problem of blind area and dead ends in tube type heat exchanger, and facilitates disassembly and cleaning.

|

04. Double tube heat exchanger

|

05. Straight type double-tube plate heat exchanger

|

06. Pipe temperature compensation electric heater, etc.

|

07. Compressed air electric heater

|

08. Filter electric heating insulation device

|